Have you ever tuned your guitar and checked its intonation, but when you play an open chord it sounds out of tune? You reach up and re-tune and now the chord sounds fine. When you play a different chord, it’s out of tune again. It’s like a cat chasing its tail. Before spending money on a new set of tuners, you may find that most of the time, the problem is with the nut.

To me, a lot of off-the-shelf guitars come with the nut unfinished. To help my customers play in tune and stay in tune, I spend extra time with every guitar detailing the nut slot edges so that strings do not bind and there’s less friction when tuning. This valuable step helps the guitar sound more open because the strings aren’t choked. If you find a string is catching when tuning or your guitar plays out of tune in the first several frets, there are some steps you can take to alleviate it.

Nut Slot is Cut Too High

If your guitar is in tune with an open string and intonated in tune at the 12th fret, but the string plays sharp at the first couple of frets, your nut is cut too high.

A set of nut files will make quick work out of deepening the slot. Fine sandpaper folded to fit the slot works well, too. Slowly go back and forth in a filing motion just a few times; then re-tune and check the note at the first fret. Repeat filing in small increments until you are in tune.

Nut Slot is Cut Too Narrow

Closely inspect the nut slots and look for dirt buildup or burrs that would make the string bind up in the slot. Also, check if the slot has been cut too tightly and is pinching the string.

Resolve this issue by grabbing a paper from a string pack and putting some Naptha on it. Run the paper through the slot a few times to remove any dirt. To remove burrs or to widen the slot, work some tightly folded 1200 grit sandpaper back-and-forth.

Nut Slot is Hanging Up the String

When a string is grabbing, a lot of players use nut sauce or graphite in the slot to reduce friction. I’m not a fan of lubricants because they tend to collect dirt and mask the real issue.

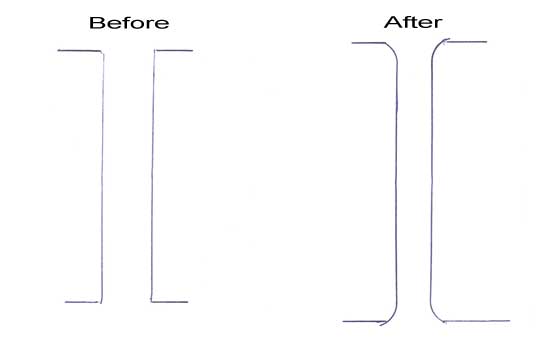

Instead, I use 1200 grit sandpaper to soften the side edges of the slot both on the front and back. Also, I use the paper to soften the front and back edge of the nut slot to make a ramping effect. Basically, I am trying to smooth any square edge so the string can travel freely and not bind up.

You have to proceed slowly and it takes some time to get it right, but I think the end result is well worth the time and effort.